Sluice Valve -IS 14846

Size : 50mm to 600mm

Scope

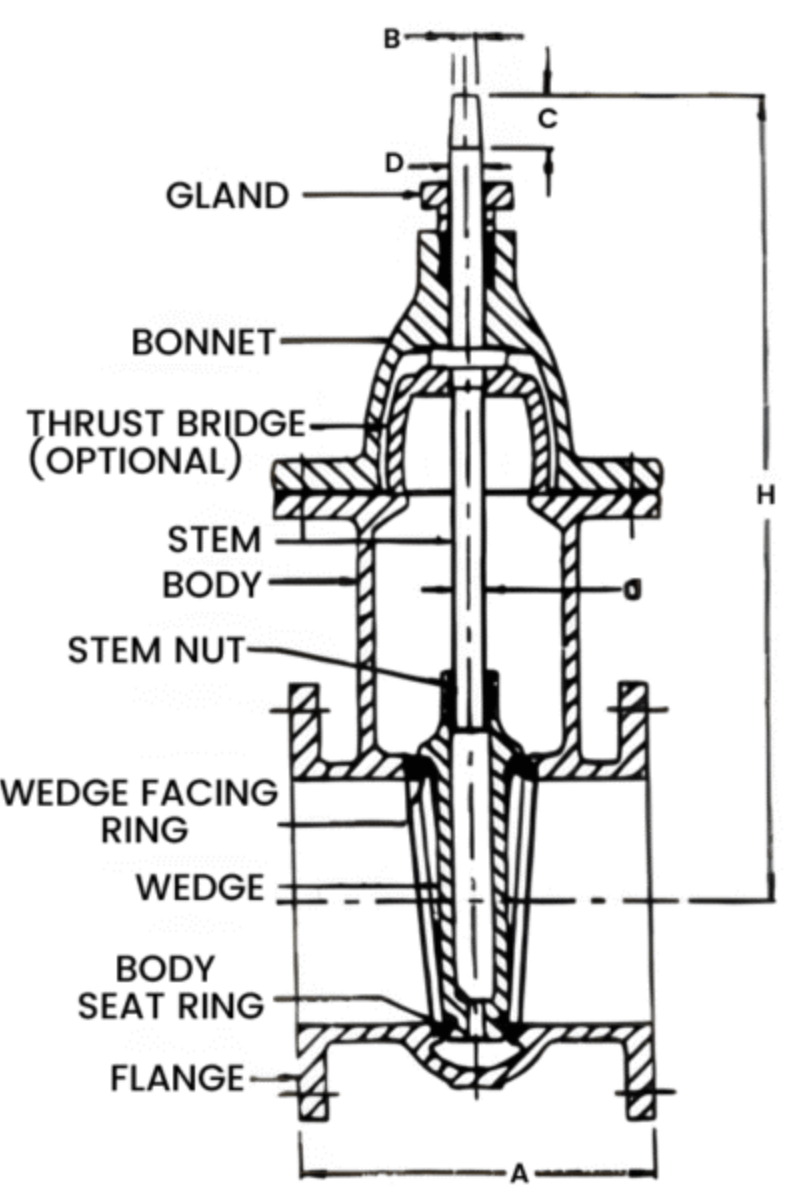

Sluice valves are key flow control devices used in waterworks systems to start or stop the flow of water. Commonly installed in main and branch pipelines, treatment plants, pumping stations, and storage tanks, they allow easy isolation of specific sections for maintenance or repair. These valves offer full-flow capacity with minimal pressure loss and are built for long-term, underground or above-ground use—making them essential for efficient water distribution.

This standard covers requirements for non-rising stem type sluice valves Pressure Rating: PN-1.0 , PN-1.6 from 5O to 1 200 mm sizes used for water supply up to 45°C and having double flanged ends for connections.

Material Table & Components

| Sl No. | Component | Preferred Material | Ref to IS No. | Grade / Designation | Alternative Material | Ref to IS No. | Grade / Designation |

|---|---|---|---|---|---|---|---|

| i | Body, bonnet, dome, stool cover, wedge, stuffing box, gland, thrust plate and cap | Grey cast iron | 210 | FG 200 | Spheroidal or Nodular iron Cast steel |

1865 1030 |

260-300/12 or 500/2 230-450W |

| ii | Hand wheel | Grey cast iron | 210 | FG 200 | Mild steel Cast steel Nodular iron |

2062 1030 1865 |

Fe 410 W A 230-450W 400/12 |

| iii | Stem | Stainless steel | 6603 | 12Cr13, 04Cr18Ni10, 04Cr17Ni12Mo2 | High Tensile Brass Stainless steel |

320 or 6912 6603 |

HT 2, PHTB 2 20Cr13 |

| iv | Wedge nut, shoe, channel | Leaded tin bronze | 318 | LTB-2 | High Tensile Brass Phosphor bronze |

320 28 |

HTB 2 PHTB-2 |

| v | Body seat ring, wedge facing ring and bushes | Leaded tin bronze | 318 | LTB-2 | Alloy steel Stainless steel |

3444 6603 |

Gr 4, Gr 10 04Cr18Ni10 |

| vi | Bolts | Carbon steel | 1363 (Part 1) | Class 4.6 | Stainless steel | 6603 | — |

| vii | Nuts | Carbon steel | 1363 (Part 3) | Class 4.0 | Stainless steel | 6603 | — |

| viii | Gasket | Rubber | 638 | Type B | Neoprene Rubber | 638 | Type B |

| ix | Gland packing | Jute and graphite | 5414 | — | Rubber | 638 | Type B |